Other Name: Silicone Water Repellent, Silicone Hydrophobic Powder, Waterproofing powder for concrete, Waterproofing powder admixture, Powder Silicone Waterproofing Powder, Silicone Waterproofing Agent Powder

Equivalent Product: Silicone Hydrophobic Powder SITREN P 750, Dow Corning SHP 50, Dow Corning SHP 60

Description

Powdered Silicone Water Repellent TPD-WR50P is produced by using polyether modified silicone oil based wetting dispersant and non-ionic surfactant to firstly make silane and siloxane into non-aqueous dispersion, and then be evenly packaged by carrier dispersion.

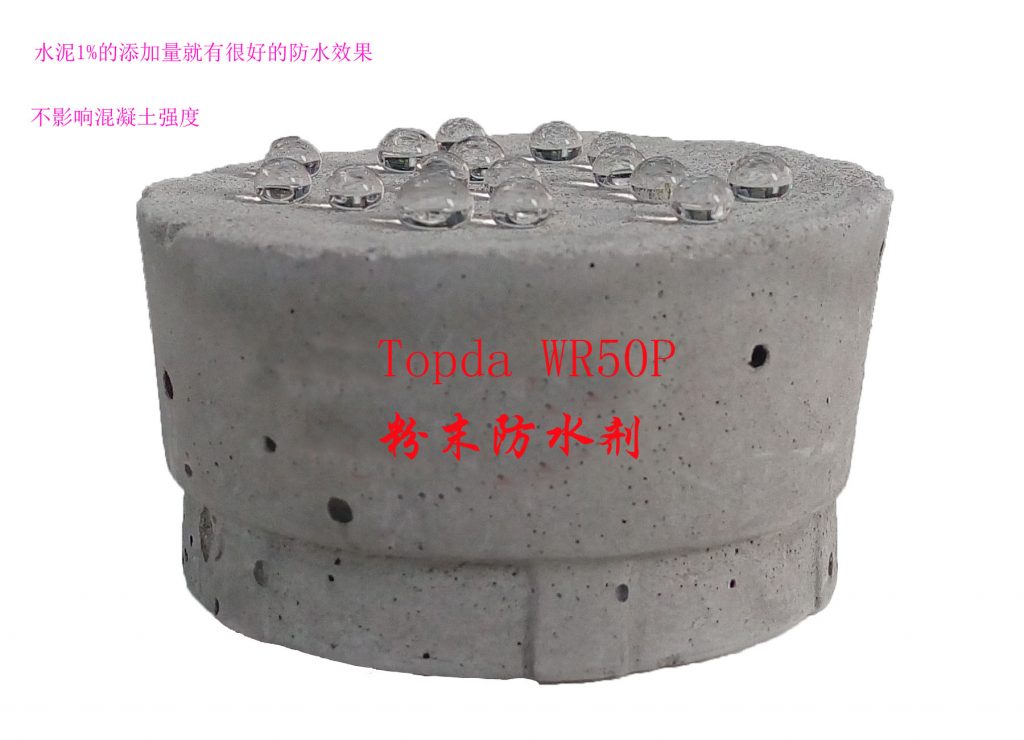

Compared with the silicone waterproofing agent used on the surface of building materials, it can be mixed into the cement powder before the molding of cement products and solidify with water together. It can make the cement products waterproof as a whole without reducing the mechanical strength of the cement products. It is convenient for packaging, storage and it is easy to use.

Features

- Convenient for packaging and transportation, easy to use.

- Super waterproofing effect, greatly reduce the water absorption rate. For concrete and mortar, the use amount is only 0.1-0.4% of the whole materials, the 48h water absorption is far superior to standard JC 474-2008.

- It is easy to disperse in the cement mortar and water.

- Not affect the final compressive strength of concrete.

Technical Index

| Item | Typical Value |

|---|---|

| Appearance | Free flowing white powder |

| Silicone Content | ≥50% |

| Density(g/cm3) | 0.4~0.6 |

Applications

1. Waterproofing powder for cement mortar

Cement: 1000g

Silica sand: 3000g

TPD-WR50P: 5-10g

Water: 1000-1200g

Table 1.

| Type of waterproofing powder

Dosage Level |

After soaking for 48 hours | |

| Water absorption, % | Water absorption ratio, % | |

| TPD-WR50P 1.0% Dosage | 2.2 | 16.3 |

| Blank reference 0% Dosage | 13.3 | – |

* Note: The amount of waterproofing powder is based on the percentage of the total amount of cement and silica sand.

Table 2.

![]()

2. Wall powder coating

Add 1% of the whole powder coating to enhance its water resistance and hydrophobic property.

3. Water based coating

Add 1%~3% of the whole water based coating, it will enhance water resistance after the coating cured film.

Packing

N.W.25KG paper bags or other packing according to clients’ request.

Transportation & Storage

1. Transported as non-hazardous chemicals.

2. After first opening the product, be sure to seal tightly and store in a cool dark place.

3. The product should be stored at temperatures between 5~30°C.

4..Avoid contact with acids and alkali substance.

Shelf Life

12 months.